|

Company

Contact us

HR MOULD INDUSTRIAL CO., LIMITED

Tel:+86-755-23079215 Fax:+86-755-23079215 Skype: hr.mould E-mail:hr@hr-mould.com Website:www.hr-mould.com Address: 1-2F, NO.3 Building, Tianyang Rd2, Dongfang Blv, Songgang Town, Baoan District, Shenzhen, China |

Project Management

Project Management

Customer-oriented management is the core value in HR Mould. We are fully aware that project management is as much important as production, especially for mould export business. This means higher efficiency, lower cost, shorter lead-time and much better operation overall control.

Basic

principles: always being honest and integrity with our customers.

Experienced and well trained project management team: a.) Well communication both in English and technical terms. b.) More than 5 years experience in export moulds with Hasco and DME Standard. c.) Quick response and timely report with Emails or phone calls to ensure the on-time commnication. d.) Just one call or an Email, you will see we are ready for you 24 hours per day, all week along.

We make our own project management system with critical quality checks at every step of process, to assure the seamless transition of customers’ idea when each project moves from the initial concept to final delivery, also assure all work be traceable and continuously improvable.

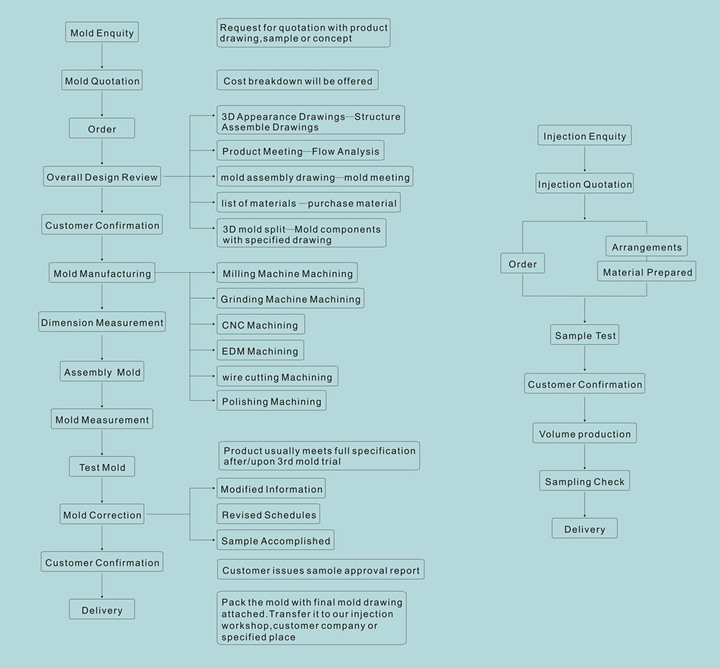

RFQ

1. Once get any RFQ, our engineer will study the technical request carefully and inform customer within 24 hours if there is any question. 2. Quotation will be available within 2-3 working days with sufficient RFQ info. 3. We will also communicate &cooperate with customer,provide suggestion to improve the project finally.

POconfirm

Once customer confirm PO,we will double check the PO details then issue proforma invoice to customer accordingly.

LayoutDesign

Design the mold assembly layout within 3-5 working days and send to customer for confirmation.

ComponentDesign

1. Design the component drawing accordingly after get mold assembly layout confirmation. 2.Purchase mold-base,mold material and layout confirmation.

WeeklyProgress

1.Status reports are available agter get mold assembly layout confimation. 2.Report the detailed project plan and cycle time. 3.Updated project weekly progress report will be sent to customer every Monday to inforn mold making status promptly.

Qualitycontrol

Project manager will monitor the quality of every production step during the whole process,there is detailded quality record for each step.

Preparetesting

1.Confirm if it is customer or us to prepare the mold material at the beginning of project. 2.We will purchase regular raw material in China for mold testing. 3.If there is any special request on plastic material,customer should provide relevant plastic before mold testing.

Moldmaking

During mold making,check the dimemsion of electrodes and mold components to enssure the quality.

Moldtesting

1. Begin 1st mold testing after mold making finished,to check if the mold structure is complete,operation is good and all function are OK. 2. Review the mold tesing situation and testing samples after 1st testing,then improve the mold and prepare for next testing.

Samplesinspection

nfirm testing sample structure and check dimension within 24 hours once finish testing sample,inform customer the result;deliver samples on customer's request.

Smallbatch

If customer need small batch production, we could arrange production and prove the good operation of mold,also could arrange packing and transportation according.

MouldInspection

1.Arrange mold simulating operation for 3-4 hours to affirm the good operation of mold. 2.Take apart mold,check and clean components;reassemble the mold,check the operation,and test cooling system by water to find to customer's request.

MouldApproval

Inform customer about inspection result,wait for final approval then preparing packing and delivery.

MouldPacking

1.Pack mold. 2.Coat mold packing with rust prevention oil. 3.Pack with plastic film to prevent any water vapor. 4.Pack with standard composite wood carton which doesn't need to be steaming and sterilizing. 5.Pack with hob for mold with big size.

MouldDelivery

Once finish all preparation, arrange mold delivery by air, sea transportation or express accordingly to customer's requirment.

Afterservice

1. Related spare parts will be provided together with mold for necessary replacement. 2.User manual is available for mold operation,to ensure mold working under normal circumstance. 3.Specific solution will be offered for any quality problem,relevant spare parts will be send to customer for replacement.

|

Copyright © 2014 HR MOULD INDUSTRIAL CO., LIMITED All Rights Reserved

Phone: +86-755-23079215 Fax:+86-755-23079215 E-mail: hr@hr-mould.com

Address: 1-2F, NO.3 Building, Tianyang Rd2, Dongfang Blv, Songgang Town, Baoan District, Shenzhen, China.